Saitama Kuki Headquarters And Main Plant

346‒0028, 5 Kawarai, Kuki city, saitama Prefecture (Kuki‒Shoubu industrial estate)

TEL.0480‒23‒0131(Representative)

FAX.0480‒22‒7896

Gunma Ota Plant

373‒0022, 1240 Higashikanai, Ota city, Gunma Prefecture

TEL.0276‒57‒8260

FAX.0480‒57‒8255

Goto Machinery Co., LTD.

372‒0022, 597-6 Hinodecho, Isesaki city, Gunma Prefecture

TEL.0270‒24‒0001

FAX.0270‒24‒0007

HIROOKA(THAILAND) CO., LTD.

88/8 Moo 8 Suwintawong Rd., T.Wangtakeian, A.Muang, Chachoengsao 24000

TEL.+66 (0) 38 847 301

FAX.+66 (0) 38 847 303

Representative

YOICHI HIROOKA, President

Establishment

March 1946

Capital

30 Million yen

Number of Employees

153(Group total 277)

Area

Kuki plant (Head office):lands 15,131㎡, buildings 7,198㎡

Ota plant:lands 8,261㎡, buildings 3,889㎡

Goto Machinery Co., LTD.:lands 19,887㎡, buildings 8,497㎡

Thiland plant:lands 13,316㎡, buildings 4,261㎡

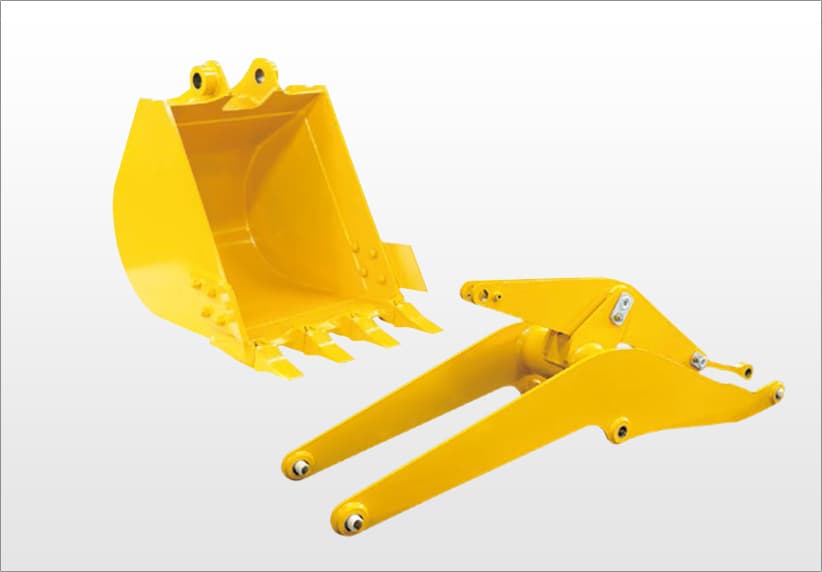

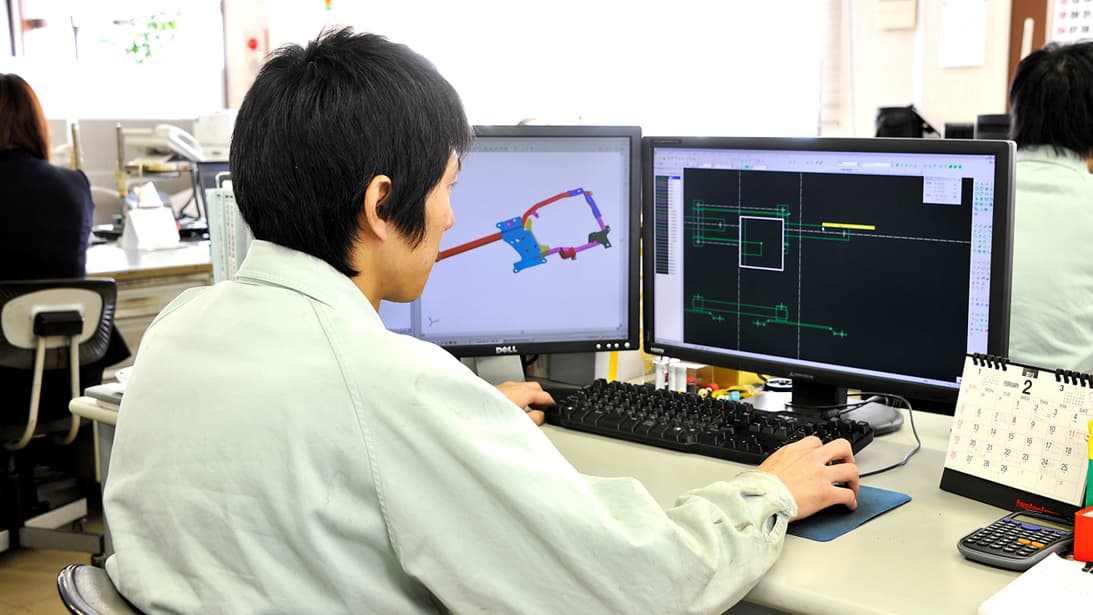

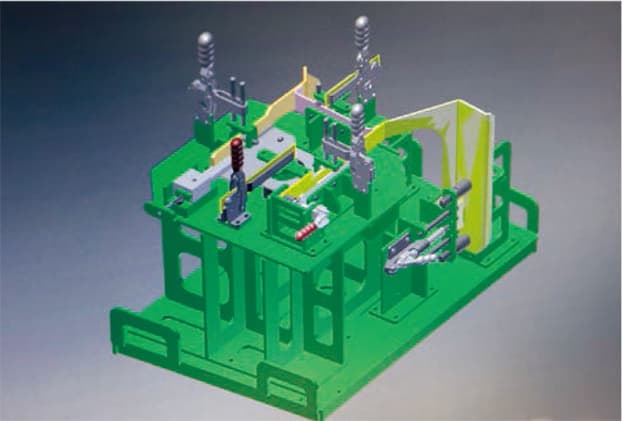

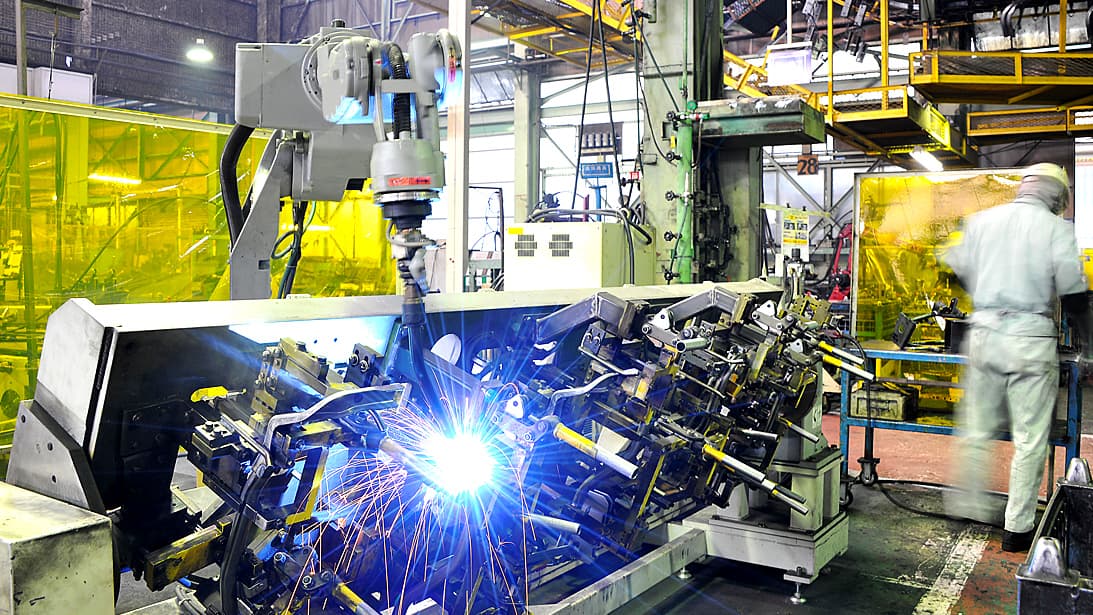

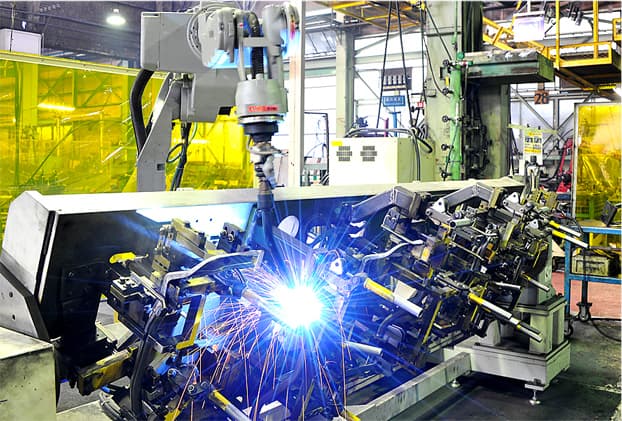

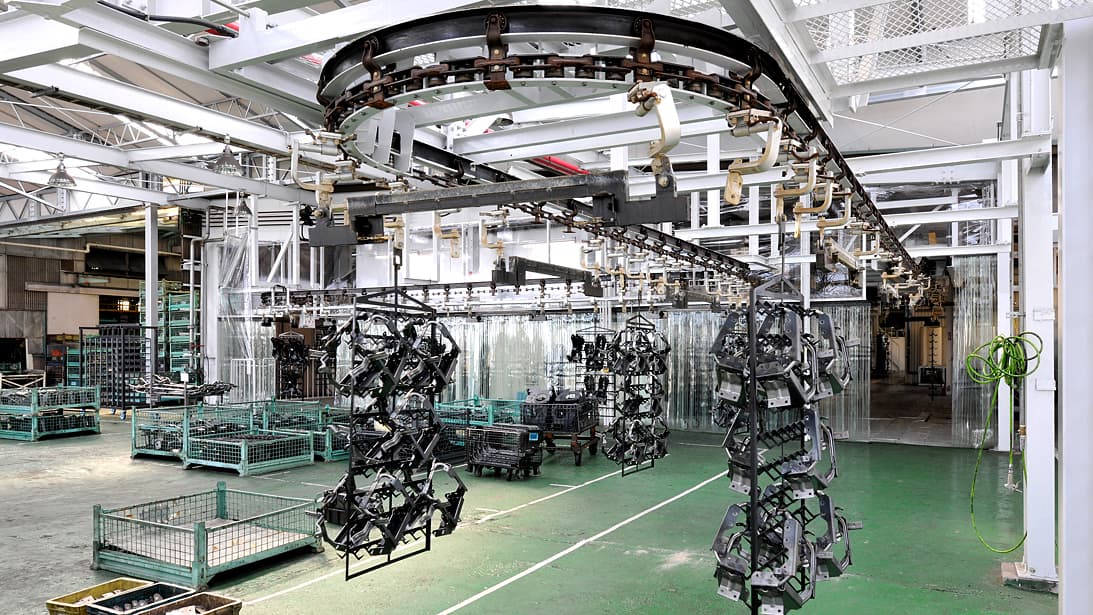

Business Contents

1.Sheet metal processing by machine press, welding, mochining, coating, assembly for automobile, construction tool, train brake,

health eqipment etc.

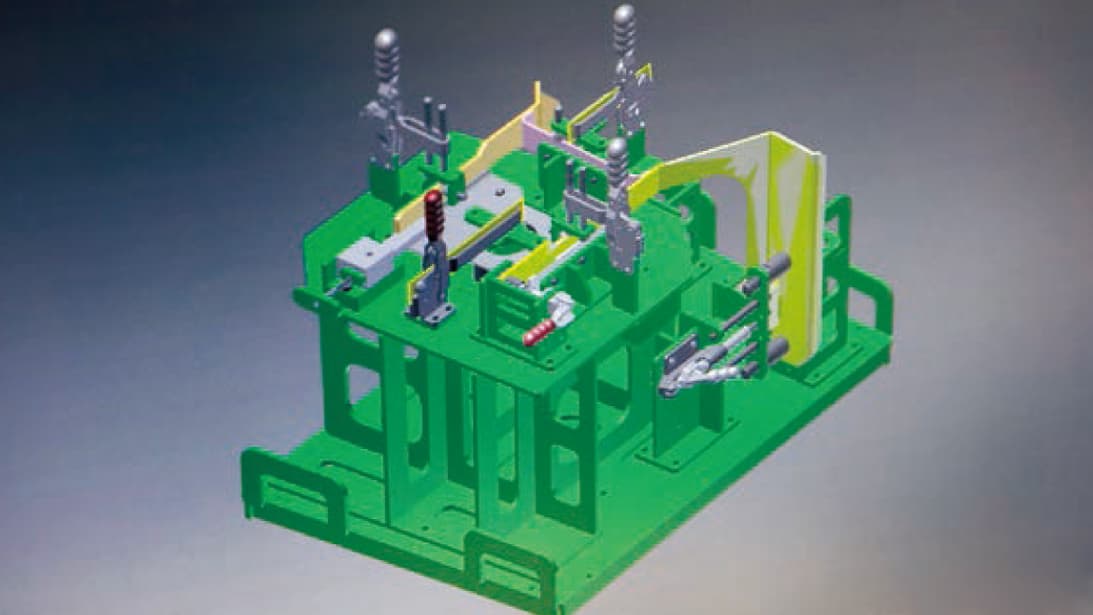

2.Design, manufacture and sale of metal mold.

Main Customers

UD Trucks Co., Ltd. / Isuzu Motors Ltd. / Komatsu Seisakusho Co., Ltd.

Banks

Japan Finance Corporation / Shoko Chukin Bank / Resona Bank / Mizuho Bank

Towa Bank / Mitsubishi Tokyo UFJ Bank